The timing of your sewing machine is crucial for producing even stitches in your cloth and making sure that all of the machine’s components are operating simultaneously.

As you go through the stages of checking and fine-tuning the timing on your machine, keep in mind that while the fundamental process for altering timing is the same for most sewing machines, the manner of removing, modifying, and installing parts is different for each machine.

Look for any further potential issues. It makes little sense to disassemble your system if you don’t have to; instead, look at other issues that could be acting like a timing issue.

Make sure your needle is fully inserted and fastened down, and that it is not broken or bent.

Verify that your bobbins are properly installed. Your machine could not operate properly if they are backward or upside-down.

Verify the compatibility of your fabric, thread weight, and needle. A bigger needle and thicker thread are needed for heavy fabrics. mrsewguru.com

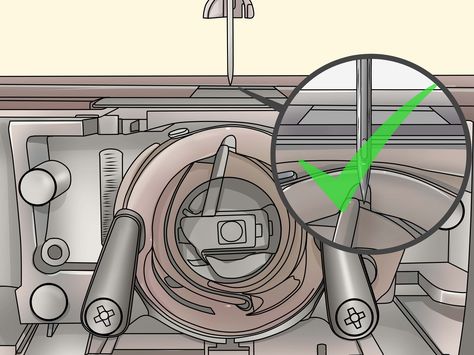

Conduct a timing test to look for a timing problem. You may check if your machine needs a timing adjustment by checking the alignment of the shuttle hook and the needle.

Remove the switchplate, base cover(s), and bobbin case while leaving the needle threaded.

To make sure the shuttle hook is smoothly capturing the thread, slowly turn the hand wheel. If not, you might need to change the timing.

To determine the time parameters, use a ruler. Put the needle at the lowest position using the hand wheel, then increase it by 3/32 of an inch. When the shuttle hook and needle are in this position, they should connect immediately above the eye. If not, you might need to change the timing.

Set up the equipment for work. Make sure you are prepared to work on your machine if you’ve decided you need to modify the timing.

The needle may need to be moved to the widest zigzag position, or you may need to alter the stitch position to a straight stitch, making sure the needle lowers through the middle of the switchplate hole. Seek advice from your manufacturer.

If you haven’t done so already, take off the machine’s switchplate, bobbin, cover, and needlebar cover.

Amplified work light, small screwdriver, sewing machine oil, and any other items you could require, should all be gathered.

Elevate the needlebar. The majority of machines feature markings that show the correct height for the needlebar. For instructions on how to access and loosen your needle bar, refer to your manual. Visit here

If there are timing marks, loosen the needlebar and move it up or down until the top timing mark is directly below the timing bar bushing.

Lower the needle entirely with the hand wheel if there are no timing marks, then elevate it by 3/32 of an inch (2.4mm). The needle’s height should be adjusted such that the eye is 3/32 of an inch below the hook’s point.

Schedule the hook time. Manufacturers and models have several ways of adjusting the hook time. However, the typical strategy is to modify the separation between the hook and the needle.

Lower the needlebar using the handwheel to its lowest setting.

At the machine’s base, loosen the gears.

For Latest Fashion News click here

Adjust the hook and needle until they are at the proper distance from one another, which can range from 0.01-0.16, depending on the machine, or 0.04 to 0.1mm.

Check again for timing precision. If your tweaks have made the machine’s settings better, you may tell by re-testing the needle and shuttle hook alignment.

Rethread the needle if you took the thread out. Keep working while leaving the bobbin region exposed.

To make sure the shuttle hook is smoothly capturing the thread, slowly turn the hand wheel. Your timing has been corrected if the hook always catches the thread.