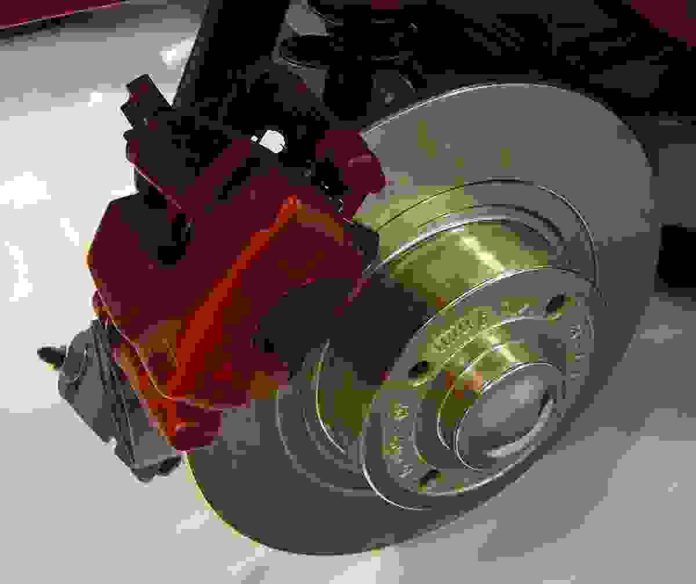

Brake brake calipers are crucial to your car’s stopping ability.Most cars today have brakes at the front.A lot of trucks and cars now have disc brakes on the rear.In a disc brake system, the car’s wheels are connected to metal discs (or rotors) that spin along with them.The caliper has the job of slowing the car’s wheels through friction with the brakes.

The brake lever fits over the brake caliper like a clamp.Each caliper contains:

A pair or plates of metal bonded to friction material.The outside brake pads go towards the curb while the inboard brake pads go toward the vehicle.Brake fluid from the mastercylinder causes hydraulic pressure on the brake caliper pistons to create hydraulic pressure, which forces the pads against your rotor.The brake pads have high friction surfaces that slow down the rotor, or bring it to an abrupt halt.Because the wheels are attached to one another, they will react as the rotor slows down or stops.

Older trucks and cars had drum brakes. Drum brakes slow down the wheels’ motion due to friction between a drum rotating and brake shoes within the drum.This friction caused heat and gas to build up in the drum. This often led to brakefading.The brake pads of disc brake systems are placed outside the drum rather than within it. This allows them to breathe more freely and prevents heat from building up.Modern cars have mostly replaced drum brakes with disc brakes. But, there are still some cheaper cars that use drum brakes on the rear wheels. These brakes require less stopping power.

There are two main types, floating (or sliding), calipers and fixed.The floating calipers move with the rotor in a straight line and have only one to two pistons.This piston pulls the entire caliper to the ground when the brakes apply, creating friction with the brake pads.Fixed calipers do not move. Instead, they have pistons that are arranged on opposite sides.Fixed calipers, while more efficient than the floating type, are still preferred for their high performance.Some fixed calipers are high-performance and have multiple pairs of pistons or “pots” on each side. Others have six.

Special tools are necessary when dealing with brakes calipers.The next section will talk about this, as well as the different types and types of brakes available for various vehicles.

Performance Brake Calipers

The disc brakes were initially designed for race cars.Race cars are known for their speed, but they also need rapid acceleration.In the early days and years of racing, cars with drum brake systems were common. Brake fade could have caused many on-track mishaps.Disc brake systems are better ventilated which reduces some of the heat and stress associated with racing.

The build-up of brake fluid can lead to brake fade.These powerful brakes gradually became more affordable for less performance-oriented vehicles.These brakes can be found on many economy cars.High-performance cars demand better brakes. However, these brakes can still be found on most economy cars.

There are limitations on the amount of vehicle brakes and their calipers can do for a vehicle to stop. However, they will only bring the wheels to a complete stop. It is up to the gripping ability of the tires to do all the rest. Even better brake parts cannot help beyond a certain point.There are many options for improving brake calipers.There are several common features that can be found in brake calipers for performance.

- Bigger pistons — A larger piston area and greater contact with brake pads will result in more clamping force on the rotor.

- Less pistonsLowend floating brakes have one piston, located on the inside.Low-end fixed Calipers have one piston, located on the inboard side.High-performance Calipers can have multiple or even two pins. They are mounted on opposing ends of the Rotor.Six-piston models and even 12-piston models become increasingly common.The clamping force can also be increased by increasing piston count.

- Less Heat Retention — In one sense, brakes are a device that converts motion into heat.All that kinetic heat generated when the vehicle slows down has to be used somewhere. The majority of it ends up being heat.It is similar to striking a match that heats up when friction exists between brake pads & rotor.If there is too much heat, the brakes become less effective and fade.Breathing properly is key to maximizing brake performance.The heat spreads more evenly the larger the brake disc.

- Differential-bore calipersAs the brake surface heats up, the clamping strength of the pistons needs to be increased in order to avoid brake fade.Multiple pistons, or multiple pairs thereof, heat the brake rotor surface. When the pistons press against the brake pad at caliper’s leading edge, it heats the brake rotor surface. It then rotates back to pistons at the trailing end of the lever to make the surface even hotter.It helps if the pistons are closer to the rear end of the caliper.Differential bore calipers use smaller pistons towards the front and larger ones toward the back.

All of these technologies may increase the braking force provided by a brake caliper.This is not necessary for smaller cars as they aren’t usually driven at high speeds.High-performance calipers are more useful for cars that are more powerful and faster.

Calipers for truck brakes

There is no doubt about it: Trucks or SUVs are huge. Sometimes, even too large.This increased size also means more momentum.Trucks and SUVs require greater stopping power than cars.What are the best ways to get the stopping power they need.Truck brakes calipers.The clamping strength determines the stopping power of a truck brake caliper. This is the force it can apply onto the surface of a rotating rotor.This is primarily dependent on the number of pistons used and the area of the brake pad (where the pad actually touches the rotor).Evidently, a clamping force that is greater than the caliper’s clamping force will be able to slow or stop a vehicle quicker and easier than a clamping force that is lower.

Many trucks are supplied with basic floating hydraulic calipers that provide sufficient power to hold the vehicle in place until it arrives at the dealer.These factory-installed floating calipers may not provide enough braking power to handle heavier loads, such as when trucks are equipped with more powerful tires or heavy accessories.There’s an extensive aftermarket for truck-calipers.The manufacturer might specify that a truck’s calipers provide a minimum of 5,000 square ml (7.8 square in) of area between the pistons (and the rotor).An aftermarket caliper may provide more than twice that amount of surface area and the clamping force required for a customized vehicle.

Truck brakes calipers deal with more heat than other parts.Heat can cause brake fade or reduce stopping distances.A good ventilation system is vital for consistent and consistent brake performance.Also, a larger brake disc (or brake rotor) can spread heat better.

Trucks and SUVs don’t require special brake equipment. But, the calipers for these heavy-weight vehicles are not without their challenges.Some people may argue that truck brake calipers should not be considered high-performance calipers.We will be discussing some of the other features high-performance brakes can offer vehicles in the next section.