Introducing Nash Plate Fin Heat Exchangers

Maintaining best operating performance in the industrial scene of today depends on effective heat transfer systems. A top choice for obtaining exceptional heat transfer in many different uses is now Nash plate fin heat exchangers. This blog will explore Nash plate fin heat exchanger design, benefits, and uses as well as how Nash vacuum pumps interact with them to improve system efficiency.

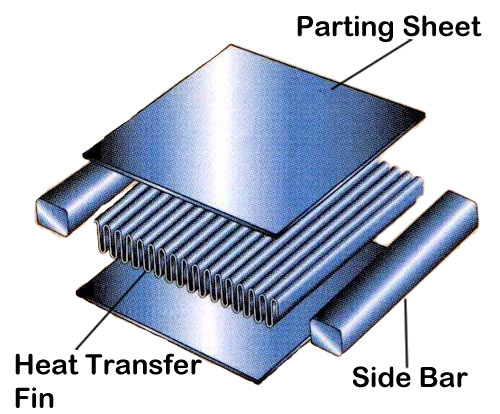

How Heat Exchangers Made by Nash Plate Fin Work

Engineers design nash plate fin heat exchangers to enhance heat transmission between two fluids. These exchangers comprise a sequence of thin plates and fins that generates several fluid flow channels. While the fins boost the surface area accessible for thermal exchange, the plates are the main surface for heat transfer. Perfect for many industrial uses, this design lets high heat transfer rates in a small and light package possible.

Advantages of Nash Plate Fin Heat Exchangers

- Excellent Heat transport Efficiency: Renowned for its capacity to effectively transport heat are Nash plate fin heat exchangers Plates and fins taken together maximize the contact surface area, guaranteeing fast and efficient heat exchange.

- These heat exchangers’ small and low weight design qualifies them for installations with limited space. Many sectors find them a sensible option as their clever utilization of space does not compromise performance.

- Over a wide range of temperatures and pressures, these heat exchangers can manage a range of fluids, including both gases and liquids, throughout. Their adaptability helps them to be applied in many industrial operations.

- Built from premium materials, Nash plate fin heat exchangers are meant to resist demanding running conditions. Their strong design guarantees dependability over time and lessens the need for regular maintenance.

Uses In Many Fields

Because of their great efficiency and adaptability, Nash plate fin heat exchangers find use in many different fields. Important applications comprise:

- These heat exchangers find usage in the aircraft industry cooling hydraulic fluids, lubricants, and other critical systems. In aircraft, where weight and space are major factors, their light-weight and small form is especially helpful.

- Automotive: Through cooling engine oils, transmission fluids, and air conditioning systems, these heat exchangers are absolutely vital in many different automotive uses. Their effectiveness aids to improve energy economy and vehicle performance.

- Nash plate fin heat exchangers are used in power plants to control fluid temperatures, therefore enhancing the efficiency of the processes of generating electricity and lowering the energy consumption.

- Chemical processing depends on these heat exchangers for exact temperature control in different operations, therefore guaranteeing effective heating and cooling of chemical reactions.

Increasing Efficiency Using Nash Vacuum Pumps

Often utilized alongside Nash plate fin heat exchangers to increase general system efficiency are Nash vacuum pumps. The required pressure differential produced by vacuum pumps helps fluid to pass through the heat exchanger channels. Nash vacuum pumps help to guarantee that the heat exchangers run at maximum efficiency by keeping ideal pressure conditions, therefore optimizing heat transfer and reducing energy consumption.

Environmental and Financial Benefits

Using Nash plate fin heat exchangers will help greatly both economically and environmentally. Their great efficiency results in lower energy use, which lowers running expenses and a smaller carbon imprint. Furthermore helping to lower long-term costs and environmental impact are these heat exchangers’ strong construction and low maintenance needs.

Next Developments and Patterns

With ongoing developments meant to increase efficiency and sustainability, Nash plate fin heat exchangers have promising future. Even more small and effective heat exchangers are predicted from developments in manufacturing technologies and materials research.

Furthermore, the incorporation of IoT (Internet of Things) features and smart technologies will revolutionize the way these heat exchangers are kept under observation. By means of real-time data collecting and analysis, one may forecast maintenance requirements, maximize performance, and minimize downtime, thereby guaranteeing optimal operation of the heat exchangers.

Conclusion

Valued for their great efficiency, small size, adaptability, and longevity, Nash plate fin heat exchangers find use in many different kinds of industry. In sectors including aerospace, automotive, power generation, and chemical processing, their flexibility to manage several fluids under different temperature and pressure conditions makes them a great choice.

These heat exchangers function much better when combined with Nash vacuum pumps, therefore guaranteeing ideal pressure conditions and maximizing heat transfer efficiency. Nash plate fin heat exchangers are destined to become progressively more ecologically friendly and efficient as technology develops, therefore supporting their central importance in contemporary industrial systems.

These heat exchangers function much better when combined with Nash vacuum pumps, therefore guaranteeing ideal pressure conditions and maximizing heat transfer efficiency. Nash plate fin heat exchangers are destined to become progressively more ecologically friendly and efficient as technology develops, therefore supporting their central importance in contemporary industrial systems.

Knowing the advantages and uses of Nash plate fin heat exchangers will help industrial operations to be much more sustainable and efficient. Investing in these sophisticated heat exchangers can help to improve temperature management, save energy, and lower environmental impact, so enhancing industrial processes.